Author Archives: admin

Environmental Report 2014

Aalborg Portland has now published its 2014 Environmental Report, including green accounts and work environment report for its Danish cement activities

In 2014, Aalborg Portland continued the planned activities set out in its action plans in order to meet its overall environmental, energy and work environment targets.

Our efforts have resulted in reducing and adjusting our consumption of electricity and fuel in line with the Danish Government’s objective to intensify efforts to save energy and desire to make use of waste and residual products, with greater emphasis on resource efficiency in what is known as a circular economy. The environmental statement includes information about the following major activities:

- In 2014, Aalborg Portland invested DKK 42 million in a facility designed to make further use of alternative fuel produced from industrial waste. The investment reduces the use of the fossil fuel such as coal and petcoke. In 2014, 33% of the energy supplied to furnace 87 was replaced by waste fuel. The goal is to replace 45% of the furnace’s fuel energy with waste in 2015.

- Our efforts in recent years to reduce the factory’s consumption of electricity and fuel, thereby limiting CO2 and NOx emissions, have generated energy savings of 222 million kWh since 2010, equivalent to the annual electricity consumption of 56,000 households.

- Emissions of NOx (nitrogen oxide) per tonne of cement have gradually decreased by 76% from 2000 to 2014 due to the establishment and optimisation of purification equipment and the use of alternative fuels.

- In the work environment area, a Task Force was set up in 2014 with the aim of looking more closely at heavy lifting. Trained members of the work environment groups have been appoint-ed to advise colleagues on the issues associated with heavy lifting

Future activities

Partnering with industrial firms and other players in society, we continue to have much focus on ex-ploiting the potential of utilising waste and residual products as a replacement for fossil fuels or natural raw materials.

In the time to come, our focus will be on maintaining the existence of a framework for a good working environment, i.a. by increased efforts directed at promoting job satisfaction, stress management and reducing workloads. We believe that a proper foundation will make us capable of reducing the number of work-related accidents. Our primary focus is on heavy lifting and falls.

The 2014 Environmental Report has been reviewed by external, certified auditors. The report con-forms to the authorities’ requirements for EMAS reports and green accounts.

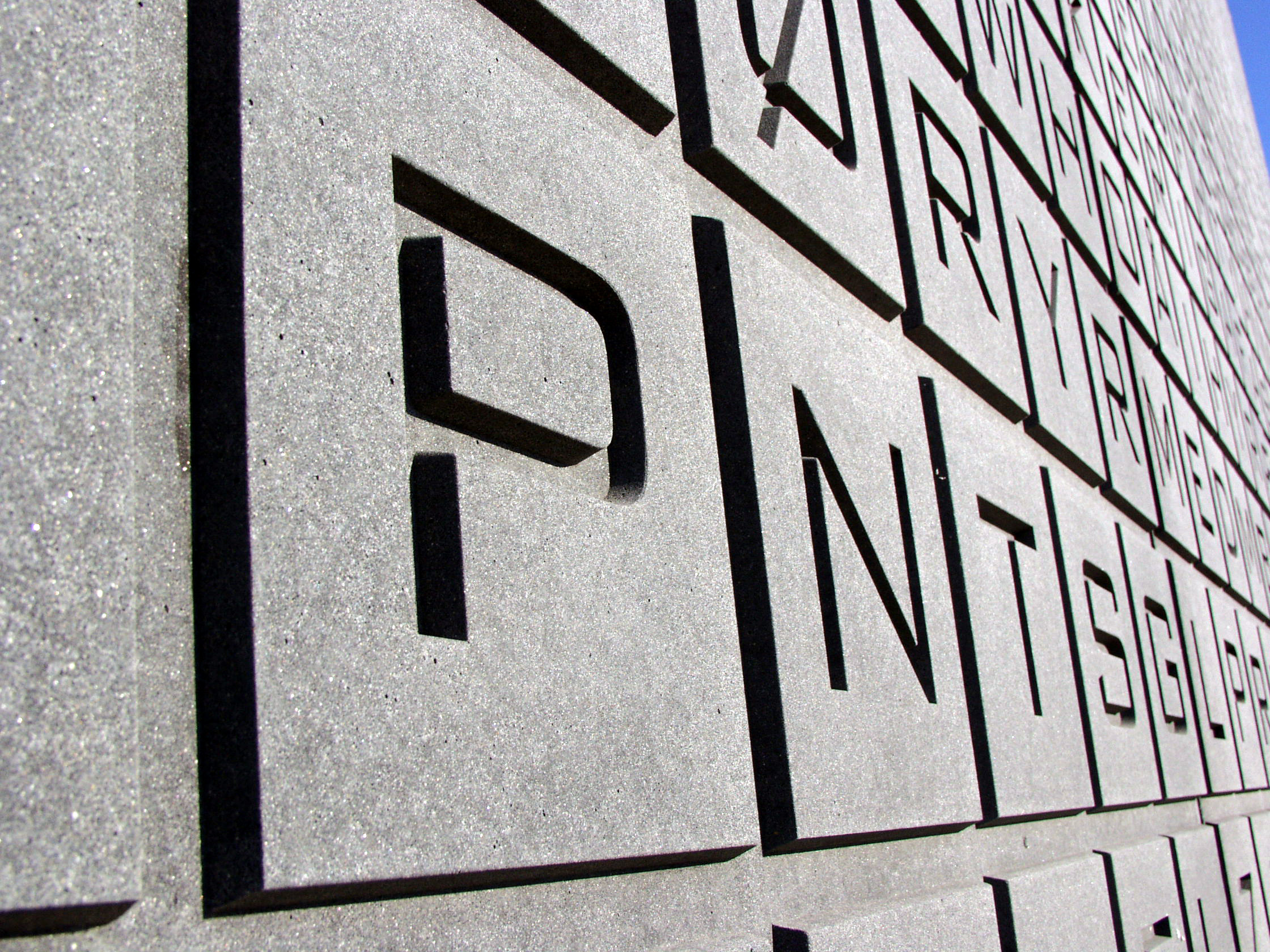

Aalborg Portland in brief

Sustainable distribution

Mettere il contenuto.

Sustainable distribution

In 2012, product distribution involved the handling of some 1.8 million tonnes of cement for transport to the domestic and export markets. Our influence

on export transport is chiefly limited to the choice of ship as the medium of carriage, and this part of the transport may therefore be designated an indirect

environmental impact.

However, in our domestic market we have better possibilities for exercising influence on the environmental impacts of transport in the form of exhaust

emissions, road wear, etc. We therefore also have a responsibility for ensuring that our distribution takes place in a sustainable manner. In 2012, 72% of our cement was distributed by ship and 28% by road tanker or lorry.

All cement manufacture takes place in Aalborg, from which the bulk of production is transported by ship to our eight Danish storage terminals strategically positioned nationwide. Onward transport to the customer is by road. Sustainable distribution The average distance from terminal to customer is just 65 km, which means we avoid long-haul transport by heavy road tankers.

This strategy continued in 2011 with the establishment of a storage facility in Aabenraa for white cement destined for export to the European market.

This facility takes 2 x 270 km of tanker transport off the motorways of Jutland as the cement is now carried to Aabenraa by ship, a more sustainable mode

of transport.

Some road haulage is contracted out to third parties. Customers in Northern Jutland are supplied direct from Aalborg. Distribution of all bagged cement

also takes place from Aalborg.

Aalborg Portland’s focus on use of alternative fuel represents an indirect CO2 benefit as this fuel is locally sourced and therefore travels a much shorter

distance than coal, petcoke and oil.

Declaration of Performance (DoP)

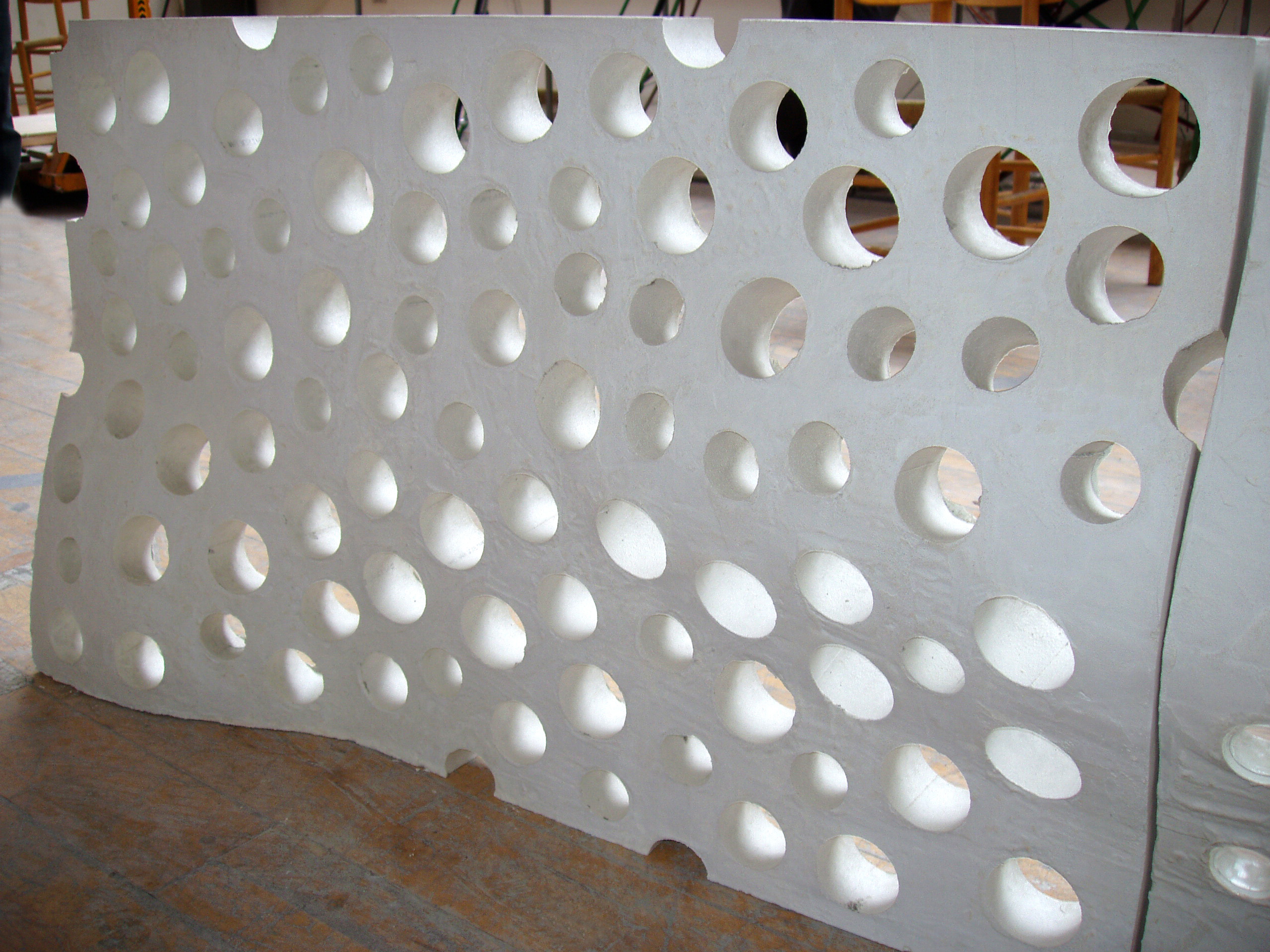

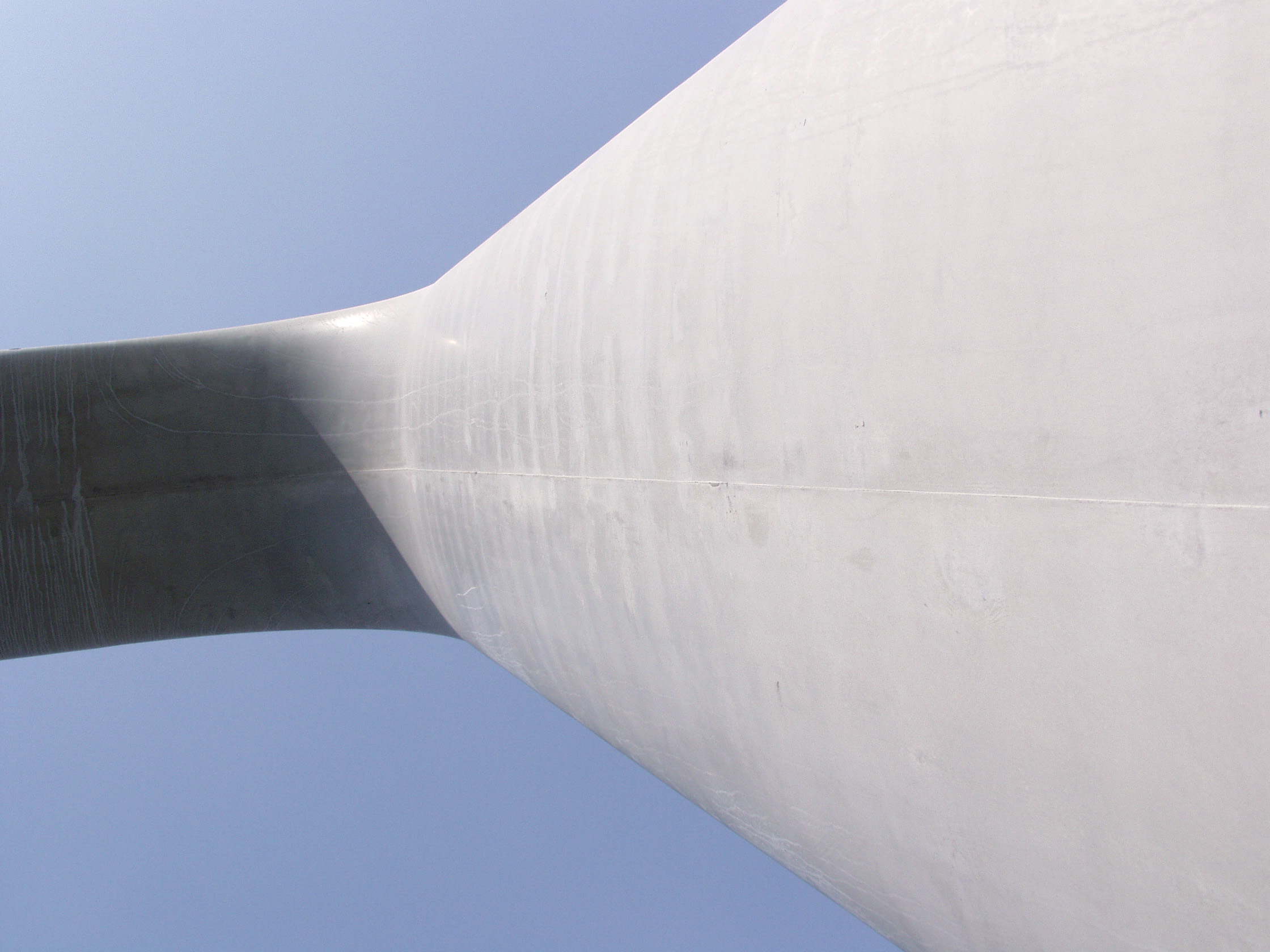

Light concrete- CAT WALK